Strong and flexible nylon fiber made from engineering biology bacteria for the first time

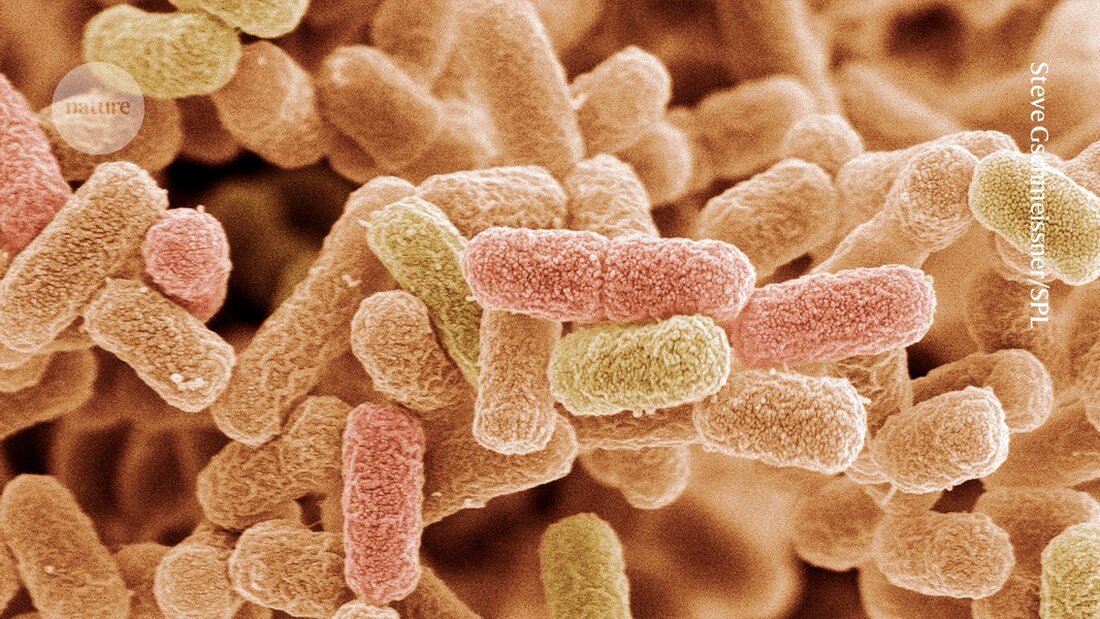

For the first time, scientists have developed genetically modified bacteria that produce flexible, nylon-like plastic.

Strong and flexible nylon fiber made from engineering biology bacteria for the first time

Researchers have genetically modified microbes to create a strong, flexible plastic similar to nylon for the first time.

In the past, bacteria have been used to generate polyesters such as polyhydroxyalkanoates (PHAs). But producing nylon-like plastics like those used in the clothing and footwear industries has been challenging, the authors report in today's issue ofNature Chemical Biology. 1

“The work is impressive,” says Colin Scott, head of enzyme engineering at Uluu, a Perth, Australia-based company that uses microbes to produce compostable PHAs from algae.

Around 400 million tons of non-degradable, petroleum-based plastic waste and microplastics are produced annually worldwide, endangering wildlife, human health and the planet. “This work highlights how much biology can do to combat this crisis,” says Scott.

Hacking nature

Bacteria naturally produce polymers to store nutrients during times of scarcity. However, using bacteria to make a nylon-like plastic is difficult because there are no naturally occurring enzymes that can create this type of polymer, explains co-author Sang Yup Lee, a biomolecular engineer at the Korea Advanced Institute of Science and Technology in Daejeon, South Korea.

To solve this problem, the researchers modified the gene-encoding genes of various bacterial species and inserted them as DNA loops called plasmidsEscherichia colia, a bacterium often used for feasibility studies.

These genes then encoded several novel enzymes that could connect molecular chains to create polymers. The final product was a bioplastic called poly(esteramide) or PEA, which was mostly polyester with some nylon-like amide bonds.

Nylon is a polymer made up of 100% amide bonds, so there's still a long way to go before bacteria can properly mimic this type of plastic, says Yup Lee.

Tests have shown that one type of PEA has physical, thermal and mechanical properties comparable to those of polyethylene, one of the most commonly used commercial plastics.

However, Seiichi Taguchi, a bioproduction engineer at Kobe University in Japan, notes that the plastic is unlikely to be as strong as polyethylene due to the low frequency at which the amino acids were incorporated into the polymers. Adding an amino acid to a polymer often results in chain disruption, creating shortened, low-molecular-weight polymers, he explains.

Commercial potential?

- Genießen Sie unsere aktuellsten Inhalte?

Melden Sie sich an oder erstellen Sie ein Konto, um fortzufahren. - Greifen Sie auf den aktuellsten Journalismus des preisgekrönten Teams von Nature zu.

- Entdecken Sie die neuesten Features und Meinungen zu bahnbrechender Forschung.

or

-

Chae, T.A. et al. Nature Chem. Biol. https://doi.org/10.1038/s41589-025-01842-2 (2025).

Suche

Suche

Mein Konto

Mein Konto